Product introduction

Oil casing

Product introduction

Oil casing is mainly used to support the well wall during drilling and after completion, so as to ensure the normal operation of the drilling process and the whole well after completion, and it is the lifeline to maintain the operation of the oil well. Due to different geological conditions, complex downhole stress state, tensile, compression, bending and torsional stresses on the pipe body, so the quality of oil casing itself is higher. The casing itself is also required to be corrosion resistant in corrosive environments. In complex geological conditions, casing is also required to have anti-crush performance. Casing can be divided into: conduit, surface casing, technical casing and reservoir casing.

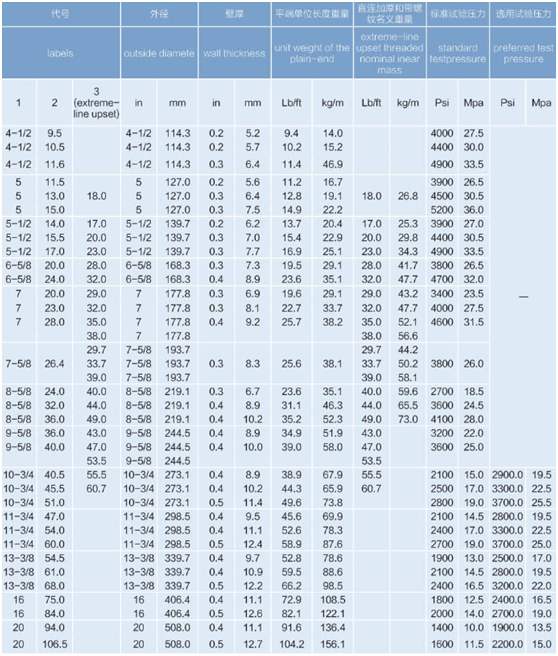

Execution standard

J55钢级石油套管API Spec 5CT 第8版(H40,K55,N80)

Petroleum Casing-grade J55(API Spec 5CT 8th edition)(H40,K55,N80)

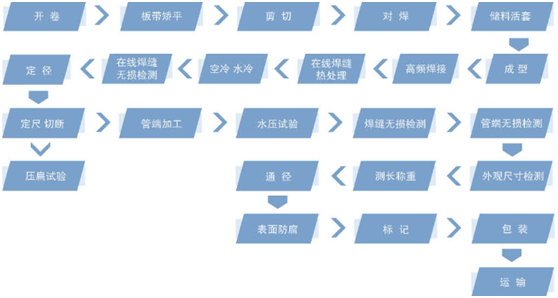

Production process

According to API Spec 5CT1988, there are 10 types of casing steel grades, including H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110, and Q-125. Casing shall be supplied with threads and couplings, or in one of the following pipe end forms: flat end, round thread with or without couplings, partial trapezoid thread with or without couplings, straight thread, special end work, sealing ring construction.

Packaging

According to SY/T6194-96, domestic casing should be tied with steel wire or steel belt. The exposed part of each sleeve and coupling thread shall be screwed with a guard ring to protect the thread.

Matters needing attention

Countermeasure of oil casing anticorrosion

1. First do a good job of water quality standards, strict water quality testing and management. Clean and separate injection should be carried out to strengthen the cleaning of the main water pipeline, so that the water quality in the station and at the bottom of the well can reach the standard and reduce the introduction of corrosion sources into the annular space.

2. For newly put into production of water injection Wells, annular protective fluid mainly used for sterilization should be added, and a system should be formed to add it regularly;

3. In view of the accelerated effect of mechanical abrasion on oil casing corrosion, it is recommended to add a rubber ring to the tubing coupling or a centralizer to the severely inclined part of the well to avoid scratching the casing and one side of the casing during the operation and water injection process;

4. In view of the serious corrosion of bacteria under scale and the slow growth and killing of SRB at high temperature, high-temperature water or steam at 100 degrees Celsius can be injected into the annulus regularly to kill SRB under scale;

5. Cathodic protection and coated casing are not recommended to be popularized until the corrosion in the casing of water injection well is effectively controlled.

Previous page

next page

Previous page

next page